Services

Competent advice

If you have any questions about our packaging and displays, we are personally available to answer them quickly. If you do not yet have a concrete idea of which packaging best suits your product, contact us via phone, e-mail or our contact form and make an appointment for a personal meeting on site or optionally for an online meeting.

We respond individually to special customer requirements. All criteria and characteristics are discussed together. With the right tips, we help with uncertainties and act solution-oriented every step of the way. The satisfaction of our customers is our top priority.

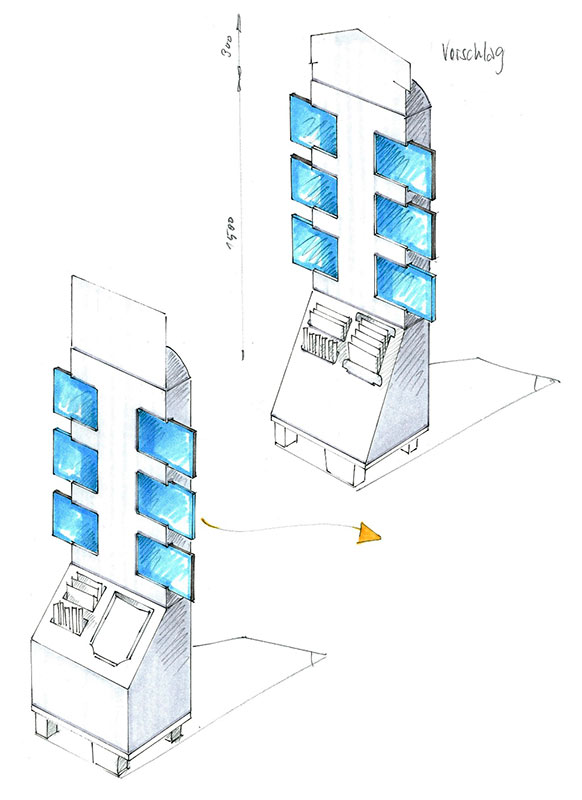

Packaging and display development

Essential when it comes to your packaging or displays. We create creative and sophisticated solutions for your product. We develop your product according to your wishes, bring in our own ideas and advise you accordingly.

After detailed consultation, our packaging developers get to work. Whether new developments or optimisations, with the help of CAD programs and 3D software your packaging or display comes to life. Functionality, feel, protection and shape are important characteristics when it comes to packaging. If required, you will receive our developed packaging for testing and inspection. We provide advice and assistance for important functional tests at your site, such as filling or erecting systems. We can ensure our packaging quality right from the development stage. Tests such as bending stiffness, stack crush or edge crush tests, burst pressure, puncture resistance, etc. can be carried out in our laboratories. Get in contact if you are interested.

We develop packaging and displays for all industries! Numerous national and international awards are proof of this. See our awards!

Digital pre-press

Your colour specifications and layouts are taken down, merged with our graphic settings and checked by our pre-press department. Depending on the printing method, our plants have their own pre-press stage for processing your print data.

Competence is the be-all and end-all in this field! Which is why we attach great importance to a high quality standard. We purchase our equipment from high-performance partners to ensure consistent quality before printing and during the printing process. This is an advantage in the event of material colour variations that can occur with a natural product such as cardboard or corrugated board. With modern technology and extensive knowledge we can counteract colour fluctuations.

Packaging printing

Offset printing and high-quality flexo printing is our answer to high-quality printing results. We offer you the most suitable printing process for best results for each packaging or display.

Packaging printing is subject to various requirements such as the properties of the starting materials from solid cardboard to corrugated cardboard, the choice of printing inks as well as the topic of finishing. Finishes such as matt, gloss, UV and effect varnishes as well as spot varnishes are no problem for us. As a printing specialist in the packaging industry, we can help you with your specific needs. Our aim is to further improve and expand our own quality model in the printing process.

Renowned international awards speak for our high-quality and convincing packaging printing.

Our printing methods:

The surface of the printing form (usually a thin flexible metal plate, very often made of aluminium) is prepared in such a way that the areas to be printed later take on the ink. We use low-migration and low-odour printing inks and coatings that are free of mineral oil.

The areas that are not to be printed are dampened with a dampening solution and do not take on any ink. The prepared printing plate is first used to print on a rubber blanket after the ink has been absorbed.

From there, the ink is then transferred to the material to be printed. In offset printing a very exact reproduction is achieved by a high resolution of the printed image.

Screen widths up to 120 lines/cm are technically feasible. In order to bring out the best in the colours, mainly coated board types – i.e. finished on the upper side with a kind of white ink – are used.

Benefits:

- Printing plates can be produced very inexpensively and quickly using the exposure process.

- Particularly fine print and high colour fastness

- Spot colours are possible

- Large print runs are possible

Flexo printing is a direct high-pressure printing process. The printing areas are higher than the non-printing areas. The ink is transferred directly to the corrugated cardboard via the higher surfaces. The flexographic printing inks are environmentally friendly and low-viscosity. An ink pump is used to pump ink from a container into the printing unit, where it is then transferred to the printing block’s surfaces for printing.

We produce printed images with a graduated screen with a resolution up to a screen width of 60L/cm. The combined use of fine screens, coated papers and fine corrugated profiles (F, E) makes our “High Quality Flexo-Postprint” a real alternative to offset and pre-print processes.

Benefits:

- Highly flexible and quick printing (just-in-time production)

- Printing blocks are very durable and can thus be used multiple times

- Low-cost production, even for small quantities

- Larger print format, therefore often one-piece production possible

Co-Packaging

From development to assembly and subsequent dispatch to your customers. Nobody knows your display as well as we do. We are very familiar with the respective requirements of logistics and transport. Therefore, we can also offer a comprehensive co-packaging service upon request. Our offer enables you not only to save costs but also time.

Warehousing and logistics

In our experience, companies do not always have the opportunity to store goods. Through structured and systematic warehousing we are able to offer you suitable solutions. Manufacture your annual packaging requirements with us and access stock at a specified time. It is important to determine your exact requirements in advance. Our solution includes sustainable shipping and transport as well as the option to view your current stocks with us via an account.